LIGHT DUTY AUTO REEL C Series

ARV50C / ARV100C

A material-friendly feeding out and winding device that automatically adjusts the optimum rotation speed and acceleration/deceleration time using a dedicated inverter with a built-in auto reel control program.

The detector detects the upper and lower limits of the material loop height and controls the main axis to start and stop rotation.

Features

Renewal

- Using a high-performance inverter supports faster line speeds (30% increase).

- The brake function is standard equipped so that it can prevent rotation caused by external forces when stopped.*1

- You can customize for your operating conditions, by optimizing maximum rotation speed, acceleration time, and more. ... Photo 1.

- The larger operation switches improves operability such as operation switching and rotation direction selection.

Supports automation

- Wide range of variations and component units mean you can combine the functions you need.

- Flexibly combine stock reels, controllers (detection methods and installation position) to match your operating conditions.

- Select the mounting position of the controller (stand-alone, mounted on main unit, or mounted on top of detector).

- Remote functions make external operations possible, such as prep work, stopping, forward inching, reverse inching, and more. ... Photo 2

High-performance

- The automatic speed changing function automatically sets the optimum rotation speed according to the line speed.

- Inverter's internal controller has many functions, including speed settings, uncoiling, winding, inching, and more. ... Photo 3

- Material loop detectors are available in contact (used for conductor) and non-contact (photoelectric sensor) types. The photoelectric sensors are available standard in two types: High sensitivity specifications and standard specifications. They can support many material specifications.

*1 Simple direct current control brake. If the external force is greater, it may rotate.

Photo 1: Front panel of controller

Photo 2: Remote switch box

Photo 3: Operation panel of controller

Specifications

| Item/Model | Vertical Auto Reel | |

|---|---|---|

| ARV50C | ARV100C | |

| Maximum load capacity (kg) | 50 | 100 |

| Maximum coil width (mm) | 100 | 150 |

| Maximum coil outside diameter (mm) | Φ800 (stock reel, K: Φ1200)*1 | |

| Coil inner diameter (mm) | Φ185 to 508 | |

| Motor capacity (W) | 100 (gear motor) | 200 (gear motor) |

| Main axis rotation speed (r/min) | 2 to 20 *2 | |

| Materials detecting method | Three types available, conductor type, standard photoelectric type, and high-sensitivity photoelectric type*3 | |

| Power source | Single phase AC 100V±10%, 50/60 Hz | |

| Triple phase AC 200V±10%, 50/60 Hz | ||

| Power consumption (VA) | 150 | 300 |

| Operating temperature (°C) | 0 to 40 | |

| Humidity (%RH) | 0 to 90 | |

| Storage temperature (°C) | -10 to 60 | |

| Atmosphere | No corrosive gas, dust or other contaminants | |

| Machine mass (kg) | 52 [13] | 73 [13] |

The mass values in the [ ] are for controller units.

*1: Stock reel K: Φ1200 is for ARV100C only.

*2: Operation is possible outside the specified range if other conditions are limited.

*3: The standard type sensor can detect materials that are at least 5 mm wide. The high-sensitivity sensor can detect materials that are at least 1 mm wide and not transparent. That is caused by the properties of photoelectric sensors. (However, if materials are cut into a grid pattern, the part (width) of the material being detected must be at least 5 mm wide or at least 1 mm wide.) Confirm that your material meets these conditions before you select a sensor.

Auto Reel Installation and Usage Precautions

The motor of the auto reel stops in a short time due to inverter control, so there is no conventional brake motor specification. However, the braking retention after the motor stops is a simple brake of the DC braking type. In the event of a power outage or significant external force, the stock reel may rotate. If such conditions are anticipated, please consult with us in advance.

Noise generated by the inverter may interfere with radios and televisions used nearby. Whenever possible, connect the power supply for the auto reel to a separate line from these devices and ensure the grounding is properly connected. If significant interference still occurs, please consult with us.

When using the auto reel with a power source that has a earth leakage breaker (ELB) or a earth leakage fire alarm installed, please ensure that the sensitivity current is 200mA or higher and the operation time is 0.1 seconds or longer. If it is lower than this, the earth leakage breaker or earth leakage fire alarm may malfunction. In such cases, it may be necessary to change the earth leakage breaker or earth leakage fire alarm, so please consult with us.

Exterior photos

Vertical Auto Reel Maximum Coil Mass 50kg

ARV50C

Vertical Auto Reel Maximum Coil Mass 100kg

ARV100C

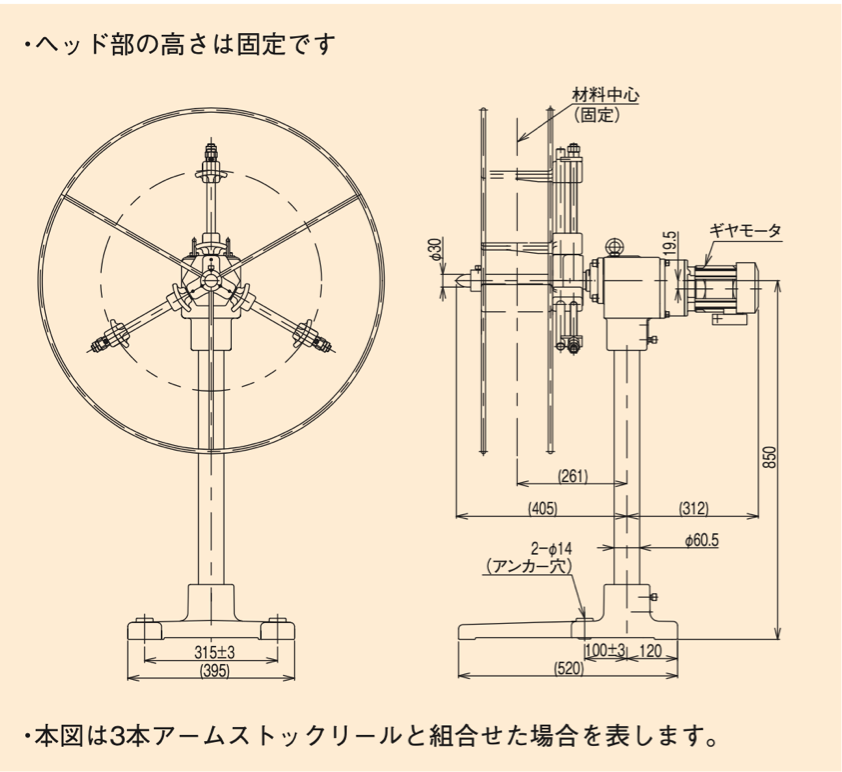

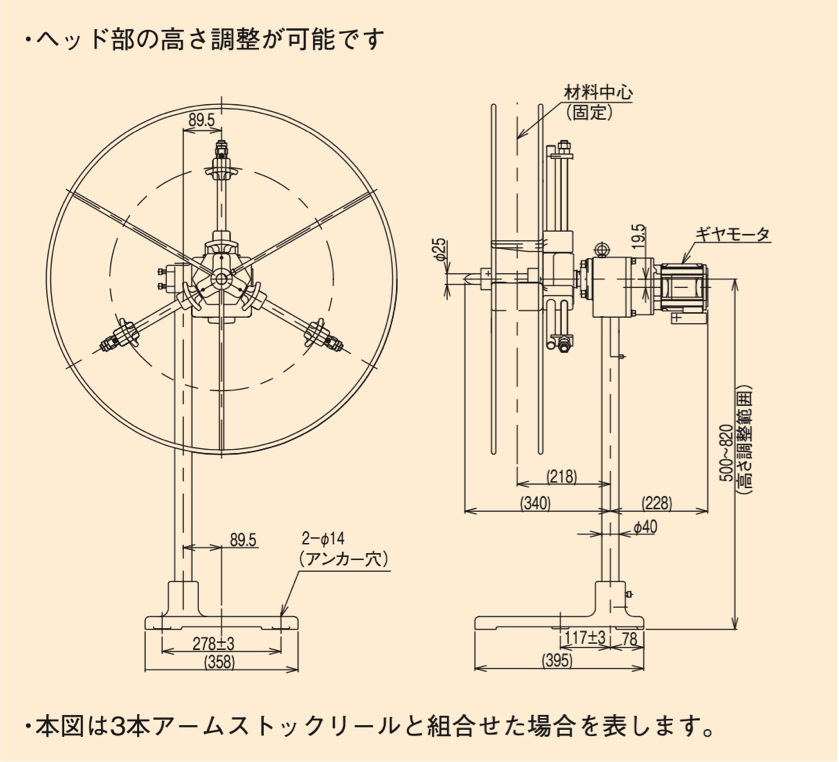

Dimensions

ARV50C

ARV100C