AIR FEEDER for automatic machines

AFA20A-NT / AFA20A-HR / AFA40A-NT / AFA40A-HR

This feeder is pneumatically driven and grip-type, suitable for hoop materials with irregularly shaped (preformed) or easily damaged.

The conventional integrated air feeder has been divided into three units, so that it can be used as a functional unit in any automatic machine.

This air feeder uses two clamps, one fixed and one movable, to alternately gripping the hoop material and feeding it by using the air cylinders.

Where, the fixed, movable clamps and feeding air cylinders are individually controlled to achieve flexible operation.

Two models are available, suitable for feeding small parts, with maximum material widths of 20mm and 40mm, respectively.

Features

Compact design and unitization make it small and light weight.

Flexible operation and configuration expands the design options for automatic machine.

Centralized control is possible from automatic machine.

Easy to incorporate into automatic lines such as automatic machines and molding machines.

Improved initial starting ability and heat resistance (100°C).

Reduced maintenance frequency.

Supports irregular shaped materials.

Specifications

| Item | Model | Remarks | |

|---|---|---|---|

| AFA20A | AFA40A | ||

| Maximum width of material (mm) | 20 | 40 | |

| Material thickness (mm) | 0.1 to 0.8 | ||

| Maximum feed length (mm) | 20 | 50 | |

| Repeatability accuracy (mm) | ±0.05 | ||

| Maximum SPM (SPM) | 200 | For feed length of 10 mm and feed angle of 180 degrees | |

| Release follow-on SPM (SPM) | 200 | For release angle of 30 degrees | |

| Fixed clamp pressing force (N) | 91 | 185 | In the case of air pressure 0.5MPa |

| Moving clamp pressing force (N) | 91 | 185 | In the case of air pressure 0.5MPa |

| Feed force (N) | Pushing 78; Pulling 120 | In the case of air pressure 0.5MPa | |

| Lubrication | Without lubrication, or Turbine oil Type 1 (ISO VG32) | Heat-resistant specifications require no lubrication. | |

| Operating air pressure (MPa) | 0.4 to 0.6 | ||

| Air consumption (L /min) | 30 | 45 | |

| Body mass (kg) | 1.7 | 2.3 | Air feeder body only |

| Operating power (V) | DC24 | When using solenoid valve unit | |

| Power consumption (W) | 0.55×3 | When using solenoid valve unit | |

| Operating temperature (°C) | 5 to 45 5 to 100 |

Room temperature specifications Heat-resistant specifications (air feeder body only) |

|

| Humidity (%RH) | 35 to 80 (No condensation) | ||

| Storage temperature (°C) | -10 to 50 | ||

| Shock/Vibration resistance (G) | 15/5 (50Hz to 1kHz) | Air feeder body only | |

*. Values for accuracy of repeatability, release follow-on SPM and maximum SPM are from our in-house tests.

*. When feeding thin materials, the material may flexion and become difficult to feed. Please add a guide to support the material or use the pull-out feeding mode.

*. Power consumption is the value when three solenoid valves in the solenoid valve unit are turned on at the same time.

*. If the ambient temperature is below 8°C, please use an air dryer (Air Filter).

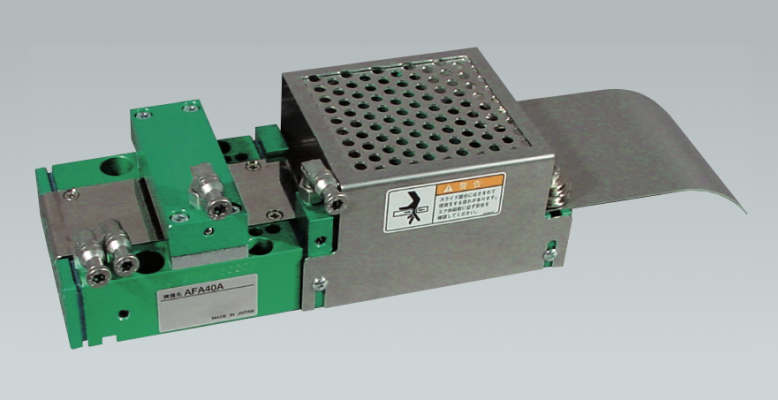

Exterior photos

Air feeder main unit (maximum material width 20mm, maximum feed length 20mm)

AFA20A-NT

Room temperature specifications (ambient temperature: 5-45°C)

AFA20A-HR

Heat-resistant specifications (ambient temperature: 5-100°C)

Air feeder main unit (maximum material width 40mm, maximum feed length 50mm)

AFA40A-NT

Room temperature specifications (ambient temperature: 5-45°C)

AFA40A-HR

Heat-resistant specifications (ambient temperature: 5-100°C)

Dimensions

AFA20A-NT

Room temperature specifications (ambient temperature: 5-45°C)

AFA20A-HR

Heat-resistant specifications (ambient temperature: 5-100°C)

AFA40A-NT

Room temperature specifications (ambient temperature: 5-45°C)

AFA40A-HR

Heat-resistant specifications (ambient temperature: 5-100°C)